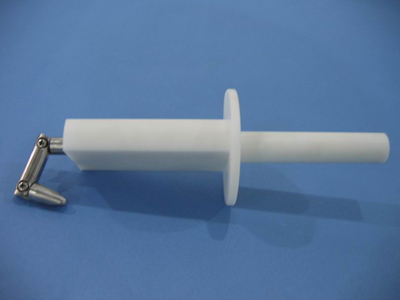

Another major difference between the UL and IEC standards is the probe used to determine accessibility of live parts and parts capable of causing injury, the UL Articulated Accessibility Probe and the IEC test finger as shown below:

1. UL Articulated Accessibility Probe

2. IEC Test Finger (test probe B of IEC 61032)

While both of these probes are applied to openings without appreciable force, if the IEC Test Finger does not enter an opening, the probe is applied in the straight position with a force of 20 N to determine if accessibility through the opening. The UL Articulated Accessibility Probe is applied to openings with a minor dimension of less than 1 in. (25.4 mm). When the minor dimension of the opening is greater, accessibility is determined by requiring no uninsulated live parts be located within a distance of five times the diameter of the largest rod which can be inserted through the opening.

3. IEC test pin

In addition to the IEC Test Finger, for IEC 60335, the IEC Test Pin (Test Probe 13 of IEC 61032) is used to determine accessibility of live parts through openings in products without a means for earthing. It is also applied to products with a means for earthing, through openings in non-metallic enclosures and metal enclosures with a non-conductive coating.

For products with visibly glowing heating elements, such as toasters, the IEC Test Probe (Probe 41 of IEC 61032) is used to determine accessibility of these live parts. For UL, accessibility of an open wire heating element for all products is determined by use of the articulated accessibility probe except for an automatic toaster, since in operation the open-wire element of an automatic toaster is radiating heat and light, and is regarded as visibly glowing. In addition, the automatic toaster is required to have a double pole switching device to disconnect the heating elements from all conductors of the supply circuit when they are in an “unenergized” state.

Nina She

Nina She